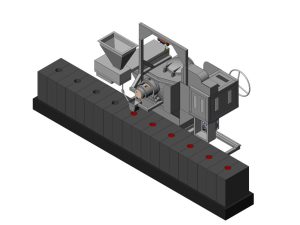

AUTOMATIC POURING MACHINES

IDEAL MODEL provides new generation automatic pouring machines which are designed to run pouring in automatic molding lines, and which could be easily integrated with the molding line with the same speed. Ladles are suitable ann designed according to molding line type and speed, having a moving car to adjust position easily. There are full automatic and semi automatic functions and equipped with automatic inoculation dosaging system, temperature meter and ladle preheating functions. It could be used in horizontal and vertical flaskless lines, horizontal line with flask. It is not a complicated system and has no extra consumable costs. Over hundreds of casting/pouring prescriptions could be recorded including name, weight, material, pouring temperature, pouring time, quantity etc.

Advantages:

- Causes no erosion while pouring inside the mold, due to free molten metal fall without any pressure.

- Automatic inoculation dosaging system could be added as an option.

- Pouring speed, poruing time, pouring amount are controlled with PLC system.

- No heating up, no extra energy cost. Molten metal is kept its temperature in desired level during the pouring with heat isolation.

- It doesn’t include consumable parts like stopper, nozzle, hydraulic sealings etc. It has less maintenance cost.

- Easy to change ladle. Ladle changing time during the operation is minimized and done automatically in the models such as LinePOUR™

- Molds which are not poured are tracked during the operation and system remembers the last casting which is done and take the position automatically after ladle changing.

- Optionally system could continue to move while making the pouring which allows molding line a continous running.

Products:

- SwingPOUR™ Automatic Pouring Ladle

- LinePOUR™ Automatic Pouring Ladle