RESIN SAND SYSTEM EQUIPMENTS

IDEAL MODEL has a deep experience and know-how related to turn-key resin sand foundries besides their own production machinery in this field. We can provide resin sand systems among with our global partners and own productions.

Some of our productions related to resin sand systems:

MOLD HANDLING MANIPLATORS:

IDEAL MODEL Mould Handling Manipulator is designed for foundries to close-up moulds, and handling of those during painting etc. operations. Special designed steel clamps grabs flask or sand molds from lateral faces and locks up with hydraulic pressure. Rotation of mechanism is also done with hydraulic pressure. Besides our hydraulic manipulators, we have options such as electrical bridge type and manual type manipulators for larger and heavier molds with flask. Systems could be adapted (connected) to monorail or bridge Crane in factory. It would have been used in flask molding foundries or flaskless (no-bake) molding systems.

MOLD COATING (DYING) UNITS:

Mold painting unit allows easy and fast painting of resin sand molds. A pneumatic pump circulates paint into the systems starting from paint resorvoir and by filtering goes back to system. Paint is easily applied on the mold bu a flexible hose and different nozzle types Paint tank and capacity must be determined by the size of mold.

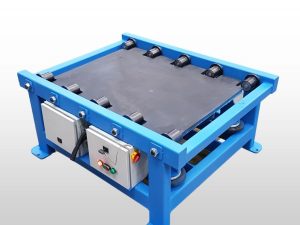

VIBRATING MOLDING TABLE:

IDEAL MODEL Vibrating Molding Table is designed for resin sand system foundries and placed under mixer to achieve homogenius sand flow over pattern and inside mold frame by vibration. System can work standalone or part of molding line.

Products:

- Mold Handling Maniplator

- Mold Coating (Dying) Unit

- Vibrating Molding Table